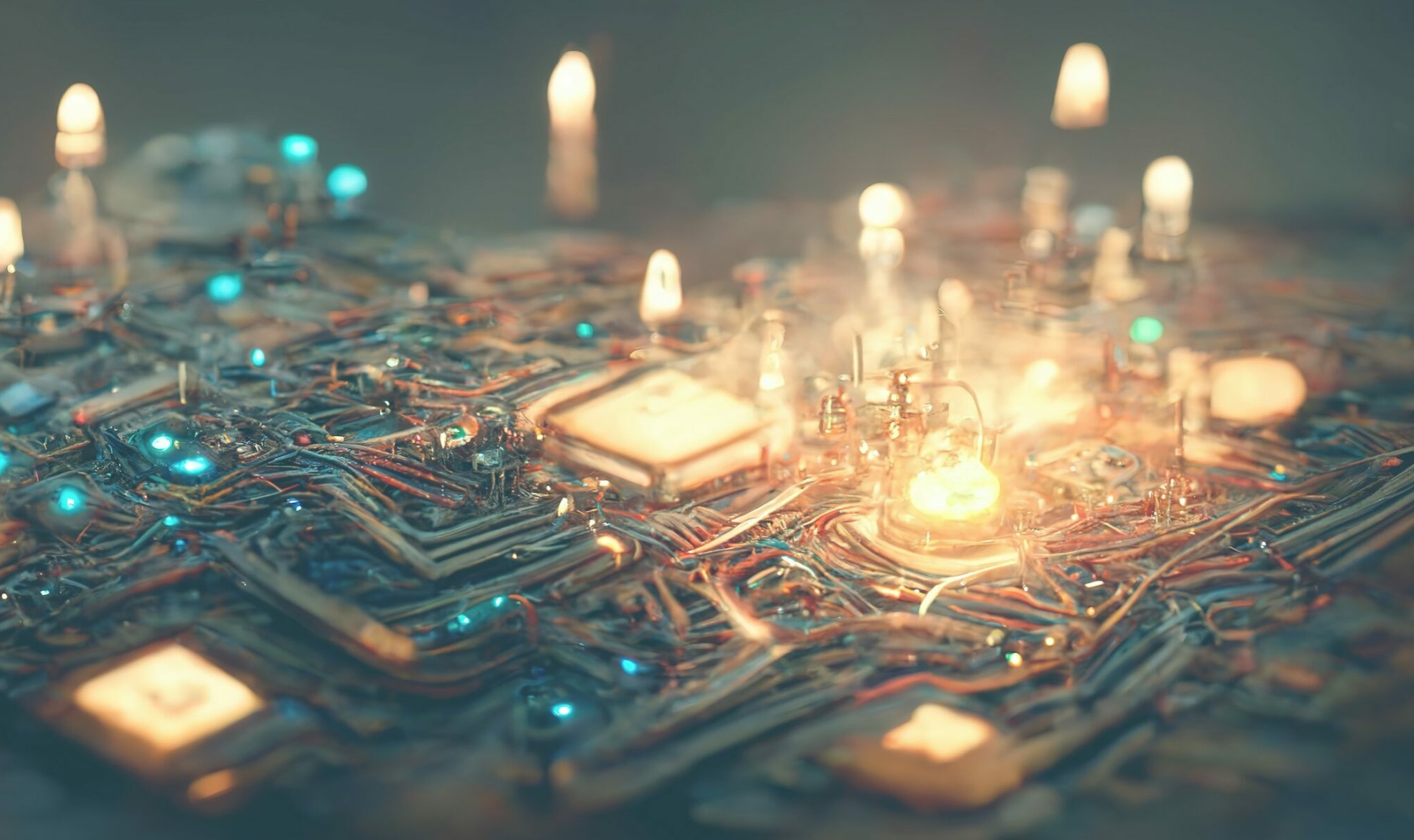

Electrochemical processes at unprecedented speed and scale

Design

Mattiq evaluates a massive design space of novel electrocatalyst materials, under a variety of relevant operating conditions, for efficiency and durability. This produces a host of promising designs for novel electrocatalytic systems.

Integrate

Mattiq synthesizes novel electrocatalysts and integrates them into prototype electrolyzers to validate key performance metrics, including production rate, selectivity, and durability.

Deploy

Mattiq optimizes the design of novel electrolyzers, and in collaboration with its manufacturing partners, deploys field-ready systems. The result is the rapid commercialization of clean chemical processes and the systematic decarbonization of the chemicals sector.

A new era of AI-guided chemical engineering

AI has transformed numerous industries, from logistics to drug discovery, enabling faster design of better products. But, due to the low quality and quantity of available data, the AI revolution had not yet reached the chemicals sector – until now.

Through design, integration, and deployment, performance data continuously feeds into Mattiq’s historical knowledge base, building predictive power for which electrochemical systems will perform well at scale – and which won’t. This generates massive datasets linking systems design to its performance across this entire development pipeline, accelerating the commercialization process for new applications and systems far beyond what is possible with traditional human-driven, linear innovation.